Flexible Subsea Solution: Adapting Equipment to the Operation

Brief Outline:

- Focused on extreme optimization of the testing and installation phases compared to conventional equipment (IWOCS).

- Delivered a solution that practically eliminates deck spread and rig mobilization of control systems.

- Completed full installation without bringing the workover system (MODFOX M2) onboard.

- Significant operational time savings for the client.

Location: Svalin, Grane Field – Norwegian Continental Shelf (NCS)

Challenge:

The client needed to optimize the testing and installation phases of a horizontal subsea tree and tubing hanger installation while minimizing rig time, equipment mobilization, and deck space usage.

Solution:

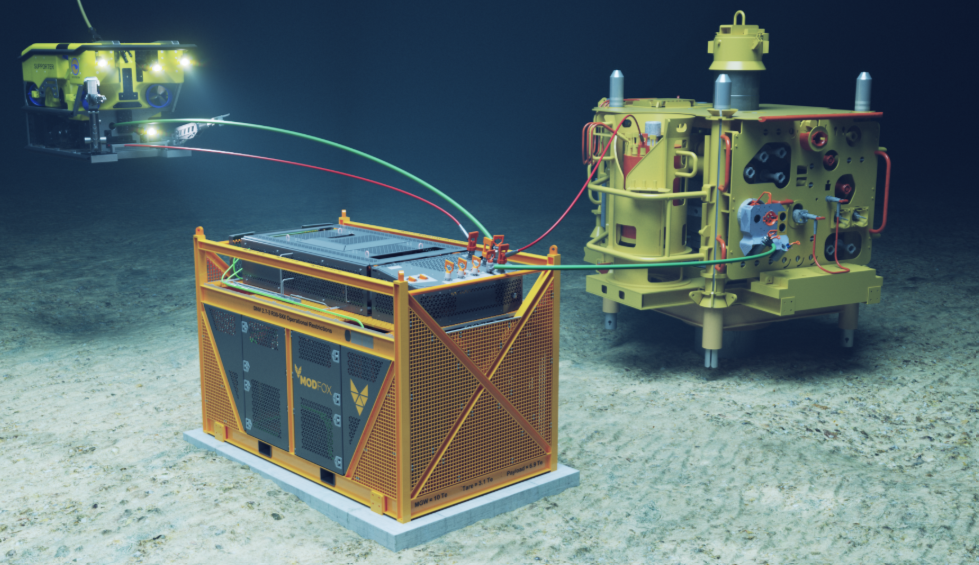

Fox Subsea proposed the MODFOX M2 system, offering unparalleled flexibility by allowing communication from the ROVs on both vessel and rig while the system remained subsea. Two topside control systems were delivered – one for the rig and one for the vessel. The subsea system is designed to withstand depths up to 3000 meters and operate subsea for over 45 days. The SUP (Subsea Umbilical Pump) provided further adaptability to meet client-specific requirements, including fluid types, pump capacity, and volume.

Result:

The project was completed successfully with seamless execution. The client achieved a more efficient and highly optimized installation and testing phase, saving substantial operational time compared to conventional legacy systems (IWOCS). By adapting the equipment to the operation — rather than forcing the operation to adapt to the equipment — we provided significant value and efficiency improvements.

Case Highlights:

- Eliminated the need for rig mobilization of workover control systems.

- Enabled fully subsea operation for the entire duration of the project.

- Delivered a flexible, dual-topside control setup (rig and vessel).

- Achieved major savings in rig time and operational costs.

By eliminating the need for rig mobilization, FOX Subsea provided real value. Their solution-driven approach helped us achieve a faster and safer project execution.

Roger Gåthe, OneSubsea