Case Study

Flexible Subsea Solution: Adapting Equipment to the Operation

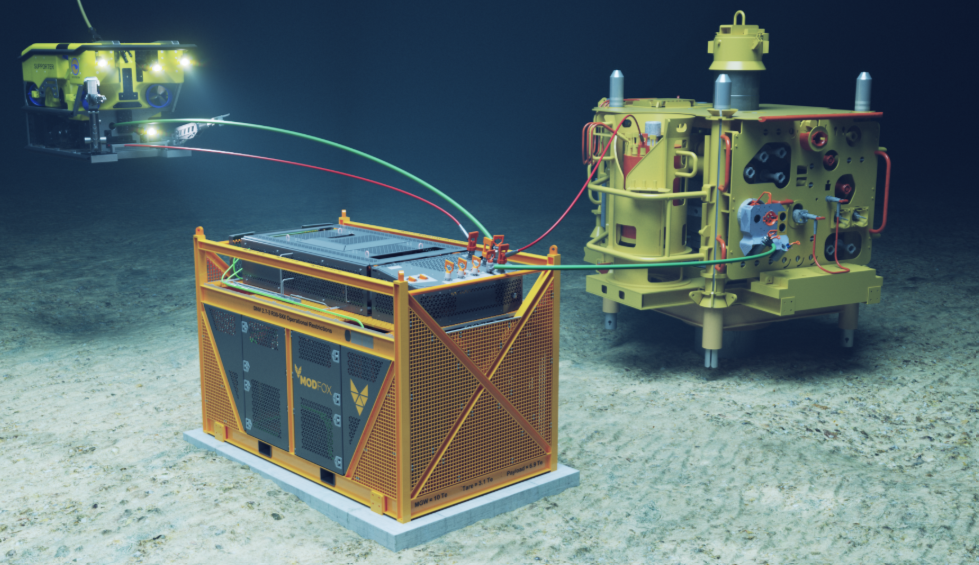

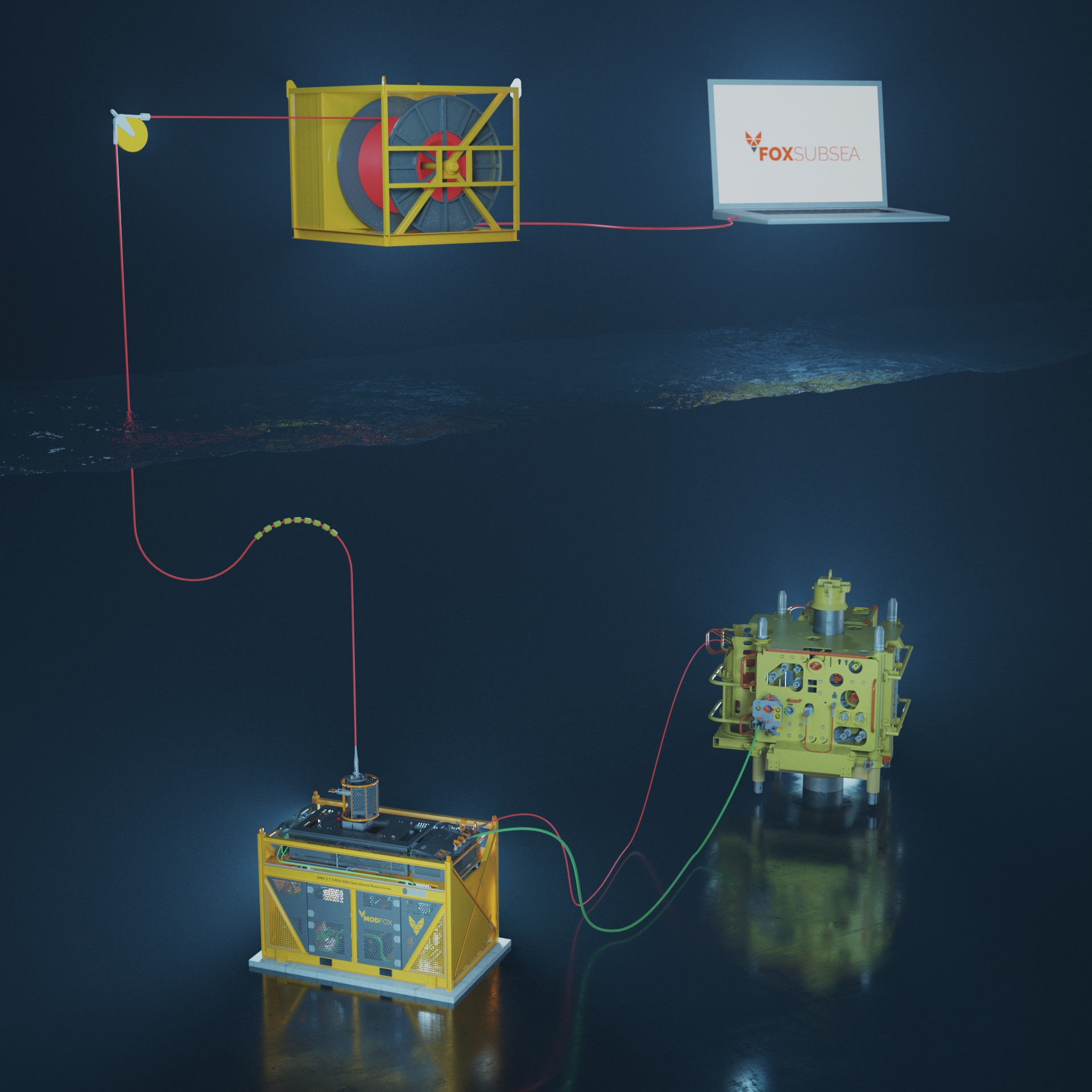

Read →Brief Outline: Location: Svalin, Grane Field – Norwegian Continental Shelf (NCS) Challenge: The client needed to optimize the testing and installation phases of a horizontal subsea tree and tubing hanger installation while minimizing rig time, equipment mobilization, and deck space usage. Solution: Fox Subsea proposed the MODFOX M2 system, offering unparalleled flexibility by allowing communication from the ROVs on both vessel and rig while the system remained subsea. Two topside control systems were delivered – one for the rig and one for the vessel. The subsea system is designed to withstand depths up to 3000 meters and operate subsea for over 45 days. The SUP (Subsea Umbilical Pump) provided further adaptability to meet client-specific requirements, including fluid types, pump capacity, and volume. Result: The project was completed successfully with seamless execution. The client achieved a more efficient and highly optimized installation and testing phase, saving substantial operational time compared to conventional legacy systems (IWOCS). By adapting the equipment to the operation — rather than forcing the operation to adapt to the equipment — we provided significant value and efficiency improvements. Case Highlights: By eliminating the need for rig mobilization, FOX Subsea provided real value. Their solution-driven approach helped us achieve…

Same Subsea System, Two Operations: Offshore Reconfiguration in Less Than a Day

Read →Brief Outline: Location: Goliat and Visund Nord, Norwegian Continental Shelf (NCS) Challenge: While operating at Goliat for Vår Energi with a MODFOX M1 system onboard the Transocean Enabler, Equinor prepared to take over the rig for operations at Visund Nord. Equinor required greater fluid capacity for their upcoming operation, making the standard M1 setup insufficient. Finding a way to adapt quickly without demobilizing equipment was critical to avoid project delays. Solution: FOX Subsea identified that the existing M1 system could be reconfigured to a MODFOX M2 setup, fulfilling the fluid capacity requirement. The reconfiguration was carried out offshore during the rig’s transit from Goliat to Visund Nord. FOX Subsea mobilized a SUP unit and service personnel, and the system was successfully modified and ready for testing onboard within 24 hours, ensuring full readiness for Equinor’s operation without interrupting the rig schedule. Result: The offshore reconfiguration enabled a seamless handover between Vår Energi and Equinor without delays or costly mobilizations. By flexibly adapting the same system to new operational needs, both operators benefitted from minimized downtime, maximized rig utilization, and optimized operational efficiency. Case Highlights: FOX Subsea showed impressive flexibility by reconfiguring the system offshore in less than 24 hours. This…

Seamless Subsea System Re-configuration for Evolving Field Needs

Read →Brief Outline: Location: Balder Field, Norwegian Continental Shelf (NCS) Challenge: Vår Energi initially requested offers for two different subsea control systems (M1 and M3) for operations from the West Phoenix rig, where only one ROV would be available. Based on our experience and system flexibility, FOX Subsea also proposed the MODFOX M2 system as an optimal solution. Following the original plan the customer selected the M3 system, suited for one of ROV on rig operation. However, shortly before execution, Vår Energi made a significant operational change — moving the installation to the Island Constructor vessel. This rendered the M3 system suboptimal for the new setup. Solution: FOX Subsea responded quickly by reconfiguring the M3 system into an M1 system within five hours at our workshop, preparing it for immediate deployment to the Island Constructor. The first campaign at Balder was successfully executed using the M1 system. Due to the tight template structures and access limitations encountered offshore, Vår Energi later opted for the M2 system for subsequent campaigns. The system was again swiftly reconfigured, highlighting its modular design and flexibility. Result: All following campaigns at Balder have been conducted using the M2 system, demonstrating the effectiveness of modular system flexibility.…